Ostriker–Peebles criterion: Difference between revisions

en>RJHall m →External links: mv to sub-cat |

en>Yobot m WP:CHECKWIKI error fixes - Replaced endash with hyphen in sortkey per WP:MCSTJR using AWB (9100) |

||

| Line 1: | Line 1: | ||

A '''spray nozzle''' is a precision device that facilitates dispersion of liquid into a [[Spray (liquid drop)|spray]]. Nozzles are used for three purposes: to distribute a liquid over an area, to increase liquid surface area, and create impact force on a solid surface. A wide variety of spray nozzle [[Spray applications|applications]] use a number of [[spray characteristics]] to describe the spray.<ref>Nasr, Yule and Bending, "Industrial Sprays and Atomization", Springer, 2002, ISBN :1-85233-611-0</ref> | |||

Spray nozzles can be categorized based on the energy input used to cause [[Aerosol|atomization]], the breakup of the fluid into drops.<ref>Lipp, C.W., Sprays Article, Kirk-Othmer Encyclopedia of Chemical Technology 5th Ed 2005</ref><ref>W.R. Marshall Jr. Atomization and Spray Drying, Am. Inst of Chem Engr. Monograph Series, 1954</ref> Spray nozzles can have one or more outlets; a multiple outlet nozzle is known as a compound nozzle. | |||

==Single-fluid nozzle== | |||

Single-fluid or hydraulic spray nozzles utilize the kinetic energy of the liquid to break it up into droplets. This most widely used type of spray nozzle is more energy efficient at producing surface area than most other types. As the fluid pressure increases, the flow through the nozzle increases, and the drop size decreases. Many configurations of single fluid nozzles are used depending on the spray characteristics desired. | |||

===Plain-orifice nozzle=== | |||

[[File:Plain orifice nozzle.png|thumb|alt=Plain orifice spray nozzle alt text|Plain orifice spray nozzle]] | |||

The simplest single fluid nozzle is a plain orifice nozzle as shown in the diagram. This nozzle often produces little if any atomization, but directs the stream of liquid. If the pressure drop is high, at least {{convert|25|bar}}, the material is often finely atomized, as in a diesel injector. At lower pressures, this type of nozzle is often used for tank cleaning, either as a fixed position compound spray nozzle or as a rotary nozzle. | |||

[[File:Flat fan nozzle.png|thumb|alt=Plat fan spray nozzle alt text|Flat fan spray pattern spray nozzle]] | |||

===Shaped-orifice nozzle=== | |||

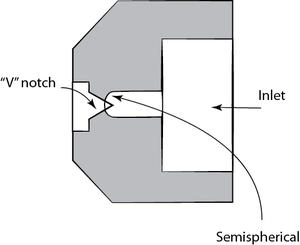

The shaped orifice uses a hemispherical shaped inlet and a ''V'' notched outlet to cause the flow to spread out on the axis of the V notch. A [[Spray characteristics#Flat Spray|flat fan]] spray results which is useful for many spray applications, such as spray painting. | |||

===Surface-impingement single-fluid nozzle=== | |||

[[Image:Impg nozzle.png|thumb|Surface impingement spray nozzle]] | |||

[[Image:spiral impingement nozzle.png|thumb|Spiral spray nozzle alt]] | |||

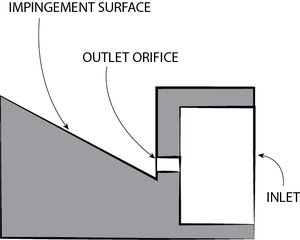

A surface impingement nozzle causes a stream of liquid to impinge on a surface resulting in a sheet of liquid that breaks up into drops. This flat fan spray pattern nozzle is used in many applications ranging from applying agricultural [[herbicides]] to row crop to painting. | |||

The impingement surface can be formed in a spiral to yield a spiral shaped sheet approximating a full cone spray pattern or a hollow-cone spray pattern.<ref>J. U. Bete, Spray Nozzles, US Patent 2,804,341, 1956</ref> | |||

The spiral design generally produces a smaller drop size than pressure swirl type nozzle design, for a given pressure and flow rate. This design is clog resistant due to the large free passage. | |||

Common applications include gas scrubbing applications (e.g., [[flue-gas desulfurization]] where the smaller droplets often offer superior performance) and fire fighting (where the mix of droplet densities allow spray penetration through strong thermal currents). | |||

===Pressure-swirl single-fluid spray nozzle=== | |||

[[Image:swirl nozzle.png|thumb|pressure swirl spray nozzle]] | |||

[[Image:Spillback Nozzle.jpg|thumb|Spillback Nozzle]] | |||

Pressure-swirl spray nozzles are high-performance (small drop size) devices with one configuration shown. The stationary core induces a rotary fluid motion which causes the swirling of the fluid in the swirl chamber. A film is discharged from the perimeter of the outlet orifice producing a characteristic hollow cone spray pattern. Air or other surrounding gas is drawn inside the swirl chamber to form an air core within the swirling liquid. Many configurations of fluid inlets are used to produce this hollow cone pattern depending on the nozzle capacity and materials of construction. The uses of this nozzle include evaporative cooling and spray drying. | |||

A spill-return pressure-swirl single-fluid nozzle is one variety of pressure swirl nozzle includes a controlled return of fluid from the swirl chamber to the feed system. This allows the nozzle pressure drop to remain high while allowing a wide range of operating rates. | |||

===Solid-cone single-fluid nozzle=== | |||

One of the configurations of the solid cone spray nozzle is shown in a schematic diagram. A swirling liquid motion is induced with the vane structure, however; the discharge flow fills the entire outlet orifice. For the same capacity and pressure drop, a full cone nozzle will produce a larger drop size than a hollow cone nozzle. The coverage is the desired feature for such a nozzle, which is often used for applications to distribute fluid over an area.. | |||

===Compound nozzle=== | |||

[[File:Compound nozzle.png|thumb|alt=Compound spray nozzle alt text|Compound pressure swirl spray nozzle with wide pattern]] | |||

A compound nozzle is a type of nozzle in which several individual single or two fluid nozzles are incorporated into on nozzle body, as shown below. This allows design control of drop size and spray coverage angle. | |||

{{-}} | |||

==Two-fluid nozzles== | |||

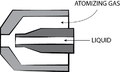

Two-fluid nozzles atomize by causing the interaction of high velocity gas and liquid. Compressed air is most often used as the atomizing gas, but sometimes steam or other gases are used. The many varied designs of two-fluid nozzles can be grouped into internal mix or external mix depending on the mixing point of the gas and liquid streams relative to the nozzle face. | |||

<gallery> | |||

Image:IMTF wiki.png|Internal mix two-fluid spray nozzle | |||

Image:EM TF wiki.png|External mix two-fluid spray nozzle | |||

Image:Laval Nozzle.JPG|TwinFluid Nozzle | |||

</gallery> | |||

===Internal-mix two-fluid nozzles === | |||

Internal mix nozzles contact fluids inside the nozzle; one configuration is shown in the figure above. Shearing between high velocity gas and low velocity liquid disintegrates the liquid stream into droplets, producing a high velocity spray. This type of nozzle tends to use less atomizing gas than an external mix atomizer and is better suited to higher viscosity streams. Many compound internal-mix nozzles are commercially used; e.g., for fuel oil atomization. | |||

===External-mix two-fluid nozzles=== | |||

External mix nozzles contacts fluids outside the nozzle as shown in the schematic diagram. This type of spray nozzle may require more atomizing air and a higher atomizing air pressure drop because the mixing and atomization of liquid takes place outside the nozzle. The liquid pressure drop is lower for this type of nozzle, sometimes drawing liquid into the nozzle due to the suction caused by the atomizing air nozzles (siphon nozzle). If the liquid to be atomized contains solids an external mix atomizer may be preferred. This spray may be shaped to produce different spray patterns. A flat pattern is formed with additional air ports to flatten or reshape the circular spray cross-section discharge. | |||

====Control of two-fluid nozzles==== | |||

Many applications use two-fluid nozzles to achieve a controlled small drop size over a range of operation. Each nozzle has a performance curve, and the liquid and gas flow rates determine the drop size.<ref>Pagcatipunan, C., Schick, R., Maximize the Performance of Spray Nozzle Systems, Chem. Engr. Progr., December 2005.</ref> Excessive drop size can lead to catastrophic equipment failure or may have an adverse effect on the process or product. For example, the gas conditioning tower in a cement plant often utilizes evaporative cooling caused by water atomized by two-fluid nozzles into the dust laden gas. If drops do not completely evaporate and strike a vessel wall dust will accumulate, resulting in the potential for flow restriction in the outlet duct, disrupting the plant operation. | |||

== Rotary atomizers == | |||

Rotary atomizers use a high speed rotating disk, cup or wheel to discharge liquid at high speed to the perimeter, forming a hollow cone spray. The rotational speed controls the drop size. Spray drying and spray painting are the most important and common uses of this technology. | |||

== Ultrasonic atomizers == | |||

This type of spray nozzle utilizes high frequency (20–50 kHz) vibration to produce narrow drop-size distribution and low velocity spray from a liquid. The vibration of a piezoelectric crystal causes capillary waves on the nozzle surface liquid film. | |||

== Electrostatic == | |||

Electrostatic charging of sprays is very useful for high transfer efficiency. Examples are the industrial spraying of coatings (paint) and applying lubricant oils. The charging is at high voltage (20–40 kV) but low current. | |||

== Nozzle performance factors<ref>Lefebvre, Arthur, ''Atomization and Sprays'', Hemisphere, 1989, ISBN '0-89116-603-3'</ref> == | |||

===Liquid properties=== | |||

Almost all drop size data supplied by nozzle manufacturers are based on spraying water under laboratory conditions, {{convert|70|°F|°C|abbr}}. The effect of liquid properties should be understood and accounted for when selecting a nozzle for a process that is drop size sensitive. | |||

===Temperature=== | |||

Liquid temperature changes do not directly affect nozzle performance, but can affect viscosity, surface tension, and specific gravity, which can then influence spray nozzle performance. | |||

=== Specific gravity === | |||

[[Specific gravity]] is the ratio of the mass of a given volume of liquid to the mass of the same volume of water. In spraying, the main effect of the specific gravity Sg of a liquid other than water is on the capacity of the spray nozzle. All vendor-supplied performance data for nozzles are based on spraying water. To determine the volumetric flowrate Q, of a liquid other than water the following equation should be used. | |||

:<math>{Q_f} = {Q_{water}}\sqrt \frac{1}{Sg}</math> | |||

===Viscosity === | |||

Dynamic [[viscosity]] is defined as the property of a liquid that resists change in the shape or arrangement of its elements during flow. Liquid viscosity primarily affects spray pattern formation and drop size. Liquids with a high viscosity require a higher minimum pressure to begin spray pattern formation and yield narrower spray angles compared to water. | |||

===Surface tension=== | |||

The [[surface tension]] of a liquid tends to assume the smallest possible size, acting as a membrane under tension. Any portion of the liquid surface exerts a tension upon adjacent portions or upon other objects that it contacts. This force is in the plane of the surface, and its amount per unit of length is surface tension. The value for water is about 0.073 N/m at 21 °C. The main effects of surface tension are on minimum operating pressure, spray angle, and drop size. Surface tension is more apparent at low operating pressures. A higher surface tension reduces the spray angle, particularly on hollow cone nozzles. Low surface tensions can allow nozzles to be operated at lower pressures. | |||

===Nozzle wear=== | |||

Nozzle wear is indicated by an increase in nozzle capacity and by a change in the spray pattern, in which the distribution (uniformity of spray pattern) deteriorates and increases drop size. Choice of a wear resistant material of construction increases nozzle life. Because many single fluid nozzles are used to meter flows, worn nozzles result in excessive liquid usage. | |||

===Material of construction=== | |||

The material of construction is selected based on the fluid properties of the liquid that is to be sprayed and the environment surrounding the nozzle. Spray nozzles are most commonly fabricated from metals, such as [[brass]], [[Stainless steel]], and [[nickel alloys]], but plastics such as [[PTFE]] and [[PVC]] and ceramics ([[alumina]] and [[silicon carbide]]) are also used. Several factors must be considered, including erosive wear, chemical attack, and the effects of high temperature. | |||

==Applications== | |||

{{see|Spray (liquid drop)}} | |||

==See also== | |||

* [[Nozzle]] | |||

* [[Nebulizer]] | |||

* [[Pesticide application]] | |||

* [[Ilass]] Institute for Liquid Atomization and Spray Systems | |||

See: [http://www.dropdata.org/DD/noz_data.htm#rotary Nozzles for ULV and CDA] | |||

==References== | |||

{{Reflist}} | |||

*[http://www.otson.com/Nozzle/Nozzle.html Spray Nozzles -Waterbase & Solvent base] — OTSON Technologies Corp | |||

{{DEFAULTSORT:Spray Nozzle}} | |||

[[Category:Nozzles]] | |||

Latest revision as of 19:36, 20 April 2013

A spray nozzle is a precision device that facilitates dispersion of liquid into a spray. Nozzles are used for three purposes: to distribute a liquid over an area, to increase liquid surface area, and create impact force on a solid surface. A wide variety of spray nozzle applications use a number of spray characteristics to describe the spray.[1]

Spray nozzles can be categorized based on the energy input used to cause atomization, the breakup of the fluid into drops.[2][3] Spray nozzles can have one or more outlets; a multiple outlet nozzle is known as a compound nozzle.

Single-fluid nozzle

Single-fluid or hydraulic spray nozzles utilize the kinetic energy of the liquid to break it up into droplets. This most widely used type of spray nozzle is more energy efficient at producing surface area than most other types. As the fluid pressure increases, the flow through the nozzle increases, and the drop size decreases. Many configurations of single fluid nozzles are used depending on the spray characteristics desired.

Plain-orifice nozzle

The simplest single fluid nozzle is a plain orifice nozzle as shown in the diagram. This nozzle often produces little if any atomization, but directs the stream of liquid. If the pressure drop is high, at least Template:Convert, the material is often finely atomized, as in a diesel injector. At lower pressures, this type of nozzle is often used for tank cleaning, either as a fixed position compound spray nozzle or as a rotary nozzle.

Shaped-orifice nozzle

The shaped orifice uses a hemispherical shaped inlet and a V notched outlet to cause the flow to spread out on the axis of the V notch. A flat fan spray results which is useful for many spray applications, such as spray painting.

Surface-impingement single-fluid nozzle

A surface impingement nozzle causes a stream of liquid to impinge on a surface resulting in a sheet of liquid that breaks up into drops. This flat fan spray pattern nozzle is used in many applications ranging from applying agricultural herbicides to row crop to painting.

The impingement surface can be formed in a spiral to yield a spiral shaped sheet approximating a full cone spray pattern or a hollow-cone spray pattern.[4]

The spiral design generally produces a smaller drop size than pressure swirl type nozzle design, for a given pressure and flow rate. This design is clog resistant due to the large free passage.

Common applications include gas scrubbing applications (e.g., flue-gas desulfurization where the smaller droplets often offer superior performance) and fire fighting (where the mix of droplet densities allow spray penetration through strong thermal currents).

Pressure-swirl single-fluid spray nozzle

Pressure-swirl spray nozzles are high-performance (small drop size) devices with one configuration shown. The stationary core induces a rotary fluid motion which causes the swirling of the fluid in the swirl chamber. A film is discharged from the perimeter of the outlet orifice producing a characteristic hollow cone spray pattern. Air or other surrounding gas is drawn inside the swirl chamber to form an air core within the swirling liquid. Many configurations of fluid inlets are used to produce this hollow cone pattern depending on the nozzle capacity and materials of construction. The uses of this nozzle include evaporative cooling and spray drying.

A spill-return pressure-swirl single-fluid nozzle is one variety of pressure swirl nozzle includes a controlled return of fluid from the swirl chamber to the feed system. This allows the nozzle pressure drop to remain high while allowing a wide range of operating rates.

Solid-cone single-fluid nozzle

One of the configurations of the solid cone spray nozzle is shown in a schematic diagram. A swirling liquid motion is induced with the vane structure, however; the discharge flow fills the entire outlet orifice. For the same capacity and pressure drop, a full cone nozzle will produce a larger drop size than a hollow cone nozzle. The coverage is the desired feature for such a nozzle, which is often used for applications to distribute fluid over an area..

Compound nozzle

A compound nozzle is a type of nozzle in which several individual single or two fluid nozzles are incorporated into on nozzle body, as shown below. This allows design control of drop size and spray coverage angle.

Benefits of Residing in a Apartment or Landed property in Singapore Property New Launches & Project Showcase In Singapore Many residential Singapore property sales involve buying property in Singapore at new launches. These are often homes underneath building, being sold new by developers. New Launch Singapore Property, 28 Imperial Residences Coming To Geylang Lorong 26 The property market is slowing down, based on personal property transactions in May Cell Apps FREE Sign Up Log in Property Brokers Feedback

Individuals all wish to be seen having the identical foresight as the experts in property investment or the massive names in their own fields. Thus the discharge of these tales works to encourage different buyers to observe suit. Bartley Ridge is the most popular new launch in district 13. Irresistible pricing from $1,1xx psf. Bartley Ridge is a ninety nine-12 months leasehold new condominium at Mount Vernon road, good next to Bartley MRT station (CC12). If you want to get more Rehda Johor chairman Koh Moo Hing said potential property consumers in the two areas Http://Modern.Dowatch.Net/Profile/Mic31K/Created/Topics are now adopting a wait-and-see attitude. How can I get the ebrochure and flooring plans of the new launch projects ? The Existing Mortgage on your HDB District 13, Freehold condominium District 11, Freehold Cluster landed house Sea Horizon EC @ Pasir Ris

FindSgNewLaunch is the main Singapore Property web site - one of the best place to begin your actual estate search whether you might be an investor, shopping for for own use, or searching for a spot to lease. With detailed details about each property, together with maps and pictures. We deliver you probably the most complete choice out there. No. For brand spanking new Singapore property gross sales, you possibly can withdraw at any time earlier than booking the unit, without penalty. On the preview, the agent will let you recognize the exact worth for you to resolve whether or not to proceed or not. Solely when you resolve to proceed will the agent book the unit for you. Pending for Sale Licence Approval All Pending for Sale Licence Approval New launch FREEHOLD condominium @ Braddell New launch condominium combined growth at Yishun PROJECT TITLE

To not worry, we'll hold you in our VIP Precedence list for future new launch VIP Preview. We'll contact you to establish your wants and advocate related tasks, both new launch or resale properties that probably match your standards. In case you're looking for resale property, such as these few years old, or just got Short-term Occupation Permit (PRIME), you might click on here right here for fast search and submit your shortlisted listings to us, we'll check and call you for viewing.

Oceanfront Suites, irresistible pricing for a 946 leasehold property with magnificent sea view. Dreaming of basking and feeling the warmth of pure sunlight is now just a click on away. Oceanfront Suites - Seaside residing no longer needs to remain an unattainable This Cambodia new launch, a mega development has also 762 residential models. Additionally located within this Oxley abroad property is a mega shopping center with 627 outlets and also up to 963 available workplace spaces and is surrounded by quite a few Embassy, resorts, Casinos and many vacationer relax space. Belysa EC @ Pasir Ris Esparina EC @ Sengkang Dell Launches World's first Gender-GEDI Female Entrepreneurship Index on 06/04/thirteen by Istanbul, Turkey. Paris Ris EC @ Paris Ris in search of indication of curiosity.

The developer should open a Venture Account with a financial institution or monetary establishment for every housing venture he undertakes, before he's issued with a Sale License (license to sell models in his development). All payments from buyers before completion of the challenge, and construction loans, go into the mission account. New launch rental LA FIESTA, an thrilling new condominium located along Sengkang Square / Compassvale Highway is a brief stroll to the bustling Sengkang City Centre the place the bus interchange, Sengkang MRT and LRT stations are located. Glorious location,Premium rental with Bayfront resort lifestyle theme and views ofwaterscape. Close to EC pricing - Worth for cash! Apr 02, 2013 Sengkang New Rental Launch, La Fiesta- Sengkang MRTstation at your gate.

As The Hillford property launch at Jalan Jurong Kechil may be very close to to beauty world mrt , the environment for the plot of land which belongs to World Class Land remains very upbeat as it is rather close to to Holland Village. Review now by visiting the brand new apartment pages on our website, each displaying complete particulars and the latest information of each new launch. You can even contact us directly to obtain quick & correct answers to all of your questions with high of the road service. An inevitable conclusion is that costs within the property market have just set new highs. The apparent connotation for potential buyers is to take motion now before prices bounce again. tract and points to his property line, marked by a big maple in a sea of Search SG Developersale.com

Two-fluid nozzles

Two-fluid nozzles atomize by causing the interaction of high velocity gas and liquid. Compressed air is most often used as the atomizing gas, but sometimes steam or other gases are used. The many varied designs of two-fluid nozzles can be grouped into internal mix or external mix depending on the mixing point of the gas and liquid streams relative to the nozzle face.

-

Internal mix two-fluid spray nozzle

-

External mix two-fluid spray nozzle

-

TwinFluid Nozzle

Internal-mix two-fluid nozzles

Internal mix nozzles contact fluids inside the nozzle; one configuration is shown in the figure above. Shearing between high velocity gas and low velocity liquid disintegrates the liquid stream into droplets, producing a high velocity spray. This type of nozzle tends to use less atomizing gas than an external mix atomizer and is better suited to higher viscosity streams. Many compound internal-mix nozzles are commercially used; e.g., for fuel oil atomization.

External-mix two-fluid nozzles

External mix nozzles contacts fluids outside the nozzle as shown in the schematic diagram. This type of spray nozzle may require more atomizing air and a higher atomizing air pressure drop because the mixing and atomization of liquid takes place outside the nozzle. The liquid pressure drop is lower for this type of nozzle, sometimes drawing liquid into the nozzle due to the suction caused by the atomizing air nozzles (siphon nozzle). If the liquid to be atomized contains solids an external mix atomizer may be preferred. This spray may be shaped to produce different spray patterns. A flat pattern is formed with additional air ports to flatten or reshape the circular spray cross-section discharge.

Control of two-fluid nozzles

Many applications use two-fluid nozzles to achieve a controlled small drop size over a range of operation. Each nozzle has a performance curve, and the liquid and gas flow rates determine the drop size.[5] Excessive drop size can lead to catastrophic equipment failure or may have an adverse effect on the process or product. For example, the gas conditioning tower in a cement plant often utilizes evaporative cooling caused by water atomized by two-fluid nozzles into the dust laden gas. If drops do not completely evaporate and strike a vessel wall dust will accumulate, resulting in the potential for flow restriction in the outlet duct, disrupting the plant operation.

Rotary atomizers

Rotary atomizers use a high speed rotating disk, cup or wheel to discharge liquid at high speed to the perimeter, forming a hollow cone spray. The rotational speed controls the drop size. Spray drying and spray painting are the most important and common uses of this technology.

Ultrasonic atomizers

This type of spray nozzle utilizes high frequency (20–50 kHz) vibration to produce narrow drop-size distribution and low velocity spray from a liquid. The vibration of a piezoelectric crystal causes capillary waves on the nozzle surface liquid film.

Electrostatic

Electrostatic charging of sprays is very useful for high transfer efficiency. Examples are the industrial spraying of coatings (paint) and applying lubricant oils. The charging is at high voltage (20–40 kV) but low current.

Nozzle performance factors[6]

Liquid properties

Almost all drop size data supplied by nozzle manufacturers are based on spraying water under laboratory conditions, Template:Convert. The effect of liquid properties should be understood and accounted for when selecting a nozzle for a process that is drop size sensitive.

Temperature

Liquid temperature changes do not directly affect nozzle performance, but can affect viscosity, surface tension, and specific gravity, which can then influence spray nozzle performance.

Specific gravity

Specific gravity is the ratio of the mass of a given volume of liquid to the mass of the same volume of water. In spraying, the main effect of the specific gravity Sg of a liquid other than water is on the capacity of the spray nozzle. All vendor-supplied performance data for nozzles are based on spraying water. To determine the volumetric flowrate Q, of a liquid other than water the following equation should be used.

Viscosity

Dynamic viscosity is defined as the property of a liquid that resists change in the shape or arrangement of its elements during flow. Liquid viscosity primarily affects spray pattern formation and drop size. Liquids with a high viscosity require a higher minimum pressure to begin spray pattern formation and yield narrower spray angles compared to water.

Surface tension

The surface tension of a liquid tends to assume the smallest possible size, acting as a membrane under tension. Any portion of the liquid surface exerts a tension upon adjacent portions or upon other objects that it contacts. This force is in the plane of the surface, and its amount per unit of length is surface tension. The value for water is about 0.073 N/m at 21 °C. The main effects of surface tension are on minimum operating pressure, spray angle, and drop size. Surface tension is more apparent at low operating pressures. A higher surface tension reduces the spray angle, particularly on hollow cone nozzles. Low surface tensions can allow nozzles to be operated at lower pressures.

Nozzle wear

Nozzle wear is indicated by an increase in nozzle capacity and by a change in the spray pattern, in which the distribution (uniformity of spray pattern) deteriorates and increases drop size. Choice of a wear resistant material of construction increases nozzle life. Because many single fluid nozzles are used to meter flows, worn nozzles result in excessive liquid usage.

Material of construction

The material of construction is selected based on the fluid properties of the liquid that is to be sprayed and the environment surrounding the nozzle. Spray nozzles are most commonly fabricated from metals, such as brass, Stainless steel, and nickel alloys, but plastics such as PTFE and PVC and ceramics (alumina and silicon carbide) are also used. Several factors must be considered, including erosive wear, chemical attack, and the effects of high temperature.

Applications

See also

- Nozzle

- Nebulizer

- Pesticide application

- Ilass Institute for Liquid Atomization and Spray Systems

References

43 year old Petroleum Engineer Harry from Deep River, usually spends time with hobbies and interests like renting movies, property developers in singapore new condominium and vehicle racing. Constantly enjoys going to destinations like Camino Real de Tierra Adentro.

- Spray Nozzles -Waterbase & Solvent base — OTSON Technologies Corp

- ↑ Nasr, Yule and Bending, "Industrial Sprays and Atomization", Springer, 2002, ISBN :1-85233-611-0

- ↑ Lipp, C.W., Sprays Article, Kirk-Othmer Encyclopedia of Chemical Technology 5th Ed 2005

- ↑ W.R. Marshall Jr. Atomization and Spray Drying, Am. Inst of Chem Engr. Monograph Series, 1954

- ↑ J. U. Bete, Spray Nozzles, US Patent 2,804,341, 1956

- ↑ Pagcatipunan, C., Schick, R., Maximize the Performance of Spray Nozzle Systems, Chem. Engr. Progr., December 2005.

- ↑ Lefebvre, Arthur, Atomization and Sprays, Hemisphere, 1989, ISBN '0-89116-603-3'