Bilinear time–frequency distribution: Difference between revisions

en>Cuzkatzimhut →Background: wikilink to virtually the "main article"! |

en>BG19bot m WP:CHECKWIKI error fix. Section heading problem. Violates WP:MOSHEAD. |

||

| Line 1: | Line 1: | ||

A '''heat flux sensor''' is a transducer that generates an electrical signal proportional to the total [[heat rate]] applied to the surface of the sensor. The measured heat rate is divided by the surface area of the sensor to determine the [[heat flux]]. | |||

The [[heat flux]] can have different origins; in principle convective, radiative as well as conductive heat can be measured. Heat flux sensors are known under different names, such as heat flux transducers, heat flux gauges, heat flux plates. Some instruments that actually are single-purpose heat flux sensors like [[pyranometers]] for solar radiation measurement. Other heat flux sensors include [[Gardon gauge]]s<ref>R.Gardon, "An instrument for the direct measurement of intense thermal radiation", Rev. Sci. Instrum., 24, 366-370, 1953.</ref> (also known as a circular-foil gauge), thin-film thermopiles,<ref>T.E. Diller, Advances in Heat Transfer, Vol. 23, p.297-298, Academic Press, 1993.</ref> and Schmidt-Boelter gauges.<ref>C.T. Kidd and C.G. Nelson, "How the Schmidt-Boelter gage really works," Proc. 41st Int. Instrum. Symp., Research Triangle Park, NC: ISA, 1995, 347-368</ref> In [[SI]] units, the [[heat rate]] is measured in [[Watt]]s, and the heat flux is computed in [[Watt]]s per meter squared. | |||

== Usage == | |||

Heat flux sensors are used for a variety of applications. Common applications are studies of building envelope thermal resistance, studies of the effect of fire and flames or laser power measurements. More exotic applications include estimation of fouling on [[boiler]] surfaces, temperature measurement of moving foil material, etc. | |||

[[File:Radiative convective hukseflux.JPG|thumb|right|400px|Typical heat flux sensor for studies of radiative- as well as convective heat flux. Photo shows model RC01 with a gold-coated and a black coated heat flux sensor on a metal heat sink. The gold sensor only measures convective heat flux, the black sensor measures radiative as well as convective heat flux. A small air temperature sensor is added to estimate local heat transfer coefficients]] | |||

The total heat flux is composed of a conductive, convective and radiative part. Depending on the application, one might want to measure all three of these quantities or single one out. An example of measurement of conductive heat flux is a heat flux plate incorporated into a wall. | |||

[[File:Hukseflux Heat Flux Plate HFP01.jpg|thumb|right|400px|Typical heat flux plate, HFP01. This sensor is typically used in the measurement of the thermal resistance of- and heat flux on building envelopes (walls, roofs). Also this sensor type can be dug in to measure soil heat flux. Diameter 80 mm]] | |||

[[File:Hukseflux radiationmeasurement sbg01 photo.jpg|thumb|right|400px|Gardon or Schmidt Boelter gauge showing the instrument main components: metal body, black sensor, water cooling pipe in and out, mounting flange, and cable. Dimensions: diameter housing is 25mm. Photo shows model SBG01.]] | |||

An example of measurement of radiative heat flux density is a [[pyranometer]] for measurement of [[solar radiation]]. | |||

An example of a sensor sensitive to radiative as well as convective heat flux is a [[Gardon gauge|Gardon]] or Schmidt–Boelter gauge, used for studies of fire and flames. The [[Gardon gauge|Gardon]] must measure convection perpendicular to the face of the sensor to be accurate due to the circular-foil construction, while the wire-wound geometry of the Schmidt-Boelter gauge can measure both perpendicular and parallel flows. | |||

In this case the sensor is mounted on a water-cooled body. Such sensors are used in fire resistance testing to put the fire to which samples are exposed to the right intensity level. | |||

There are various examples of sensors that internally use heat flux sensors examples are laser power meters, pyranometers, etc. | |||

We will discuss three large fields of application in what follows.<ref name="Hukseflux Applications and Specifications">{{cite web|url=http://www.hukseflux.com/downloads/thermalScience/applicAndSpec.pdf|title=Hukseflux Thermal Sensors Applications and Specifications paper}}</ref> | |||

=== Applications in meteorology and agriculture === | |||

Soil heat flux is a most important parameter in agro-meteorological studies, since it allows one to study the amount of energy stored in the soil as a function of time. | |||

Typically two or three sensors are buried in the ground around a meteorological station at a depth of around 4 cm below the surface. The problems that are encountered in soil are threefold: | |||

: First is the fact that the thermal properties of the soil are constantly changing by absorption and subsequent evaporation of water. | |||

: Second, the flow of water through the soil also represents a flow of energy, going together with a ''thermal shock'', which often is misinterpreted by conventional sensors. | |||

: The third aspect of soil is that by the constant process of wetting and drying and by the animals living on the soil, the quality of the contact between sensor and soil is not known. | |||

The result of all this is the quality of the data in soil heat flux measurement is not under control; the measurement of soil heat flux is considered to be extremely difficult. | |||

=== Applications in building physics === | |||

In a world ever more concerned with saving energy, studying the thermal properties of buildings has become a growing field of interest. One of the starting points in these studies is the mounting of heat flux sensors on walls in existing buildings or structures built especially for this type of research. | |||

The measurement of heat flux in walls is comparable to that in soil in many respects. Two major differences however are the fact that the thermal properties of a wall generally do not change (provided its moisture content does not change) and that it is not always possible to insert the heat flux sensor in the wall, so that it has to be mounted on its inner or outer surface. | |||

When the heat flux sensor has to be mounted on the surface of the wall, one has to take care that the added [[thermal resistance]] is not too large. Also the spectral properties should be matching those of the wall as closely as possible. If the sensor is exposed to [[solar radiation]], this is especially important. In this case one should consider painting the sensor in the same color as the wall. Also in walls the use of self-calibrating heat flux sensors should be considered.<ref name="greenTEG Application note Building Physics">{{cite web|url=http://www.greenteg.com/applications/heat-flux-sensing/building-physics/|title=greenTEG Application Note Building Physics}}</ref> | |||

=== Applications in medical studies === | |||

The measurement of the heat exchange of human beings is of importance for medical studies, and when designing clothing, immersion suits and sleeping bags. | |||

A difficulty during this measurement is that the human skin is not particularly suitable for the mounting of heat flux sensors. Also the sensor has to be thin: the skin essentially is a constant temperature heat sink, so added thermal resistance has to be avoided. Another problem is that test persons might be moving. The contact between the test person and the sensor can be lost. For this reason, whenever a high level of quality assurance of the measurement is required, it can be recommended to use a self-calibrating sensor. | |||

== Properties == | |||

A heat flux sensor should measure the local heat flux density in one direction. The result is expressed in watts per square meter. The calculation is done according to: | |||

<math>\phi_q =\frac{V_{\mathrm{sen}}}{E_{\mathrm{sen}}}</math> | |||

Where <math>V_{\mathrm{sen}}</math> is the sensor output and <math>E_{\mathrm{sen}}</math> is the calibration constant, specific for the sensor. | |||

[[Image:generalhfsensor.png|thumb|250px|left|General characteristics of a heat flux sensor.]] | |||

As shown before in the figure to the left, heat flux sensors generally have the shape of a flat plate and a sensitivity in the direction perpendicular to the sensor surface. | |||

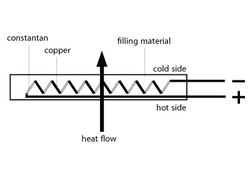

Usually a number of [[thermocouple]]s connected in series called thermopiles are used. General advantages of thermopiles are their stability, low ohmic value (which implies little pickup of electromagnetic disturbances), good signal-noise ratio and the fact that zero input gives zero output. Disadvantageous is the low sensitivity. | |||

For better understanding of heat flux sensor behaviour, it can be modeled as a simple electrical circuit consisting of a resistance, <math>R</math>, and a capacitor, <math>C</math>. In this way it can be seen that one can attribute a thermal resistance <math>R_{\mathrm{sen}}</math>, a thermal capacity <math>C_{\mathrm{sen}}</math> and also a response time <math>\tau_{\mathrm{sen}}</math> to the sensor. | |||

Usually, the thermal resistance and the thermal capacity of the entire heat flux sensor are equal to those of the filling material. Stretching the analogy with the electric circuit further, one arrives at the following expression for the response time: | |||

<math>\tau_{\mathrm{sen}} = R_{\mathrm{sen}} C_{\mathrm{sen}} = \frac{d^2 \rho C_p}{\lambda}</math> | |||

In which <math>d</math> is the sensor thickness, <math>\rho</math> the density, <math>C_p</math> the specific heat capacity and <math>\lambda</math> the thermal conductivity. From this formula one can conclude that material properties of the filling material and dimensions are determining the response time. | |||

As a rule of thumb, the response time is proportional to the thickness to the power of two. | |||

Other parameters that are determining sensor properties are the electrical characteristics of the thermocouple. The temperature dependence of the thermocouple causes the temperature dependence and the non-linearity of the heat flux sensor. The non linearity at a certain temperature is in fact the derivative of the temperature dependence at that temperature. | |||

However, a well designed sensor may have a lower temperature dependence and better linearity than expected. There are two ways of achieving this: | |||

:As a first possibility, the thermal dependence of conductivity of the filling material and of the thermocouple material can be used to counterbalance the temperature dependence of the voltage that is generated by the thermopile. | |||

:Another possibility to minimise the temperature dependence of a heat flux sensor, is to use a resistance network with an incorporated thermistor. The temperature dependence of the thermistor will balance the temperature dependence of the thermopile. | |||

Another factor that determines heat flux sensor behaviour, is the construction of the sensor. In particular some designs have a strongly nonuniform sensitivity. Others even exhibit a sensitivity to lateral fluxes. The sensor schematically given in the above figure would for example also be sensitive to heat flows from left to right. This type of behaviour will not cause problems as long as fluxes are uniform and in one direction only. | |||

[[Image:sandwichconstruction.png|thumb|250px|left|Sandwich construction.]] | |||

To promote uniformity of sensitivity, a so-called sandwich construction as shown in the figure to the left can be used. The purpose of the plates, which have a high conductivity, is to promote the transport of heat across the whole sensitive surface. | |||

It is difficult to quantify non-uniformity and sensitivity to lateral fluxes. Some sensors are equipped with an extra electrical lead, splitting the sensor into two parts. If during application, there is non-uniform behaviour of the sensor or the flux, this will result in different outputs of the two parts. | |||

Summarising: The intrinsic specifications that can be attributed to heat flux sensors are thermal conductivity, total thermal resistance, heat capacity, response time, non linearity, stability, temperature dependence of sensitivity, uniformity of sensitivity and sensitivity to lateral fluxes. For the latter two specifications, a good method for quantification is not known. | |||

== Error sources == | |||

The interpretation of measurement results of heat flux sensors is often done assuming that the phenomenon that is studied, is quasi-static and taking place in a direction transversal to the sensor surface. | |||

Dynamic effects and lateral fluxes are possible error sources. | |||

=== Dynamic effects === | |||

The assumption that conditions are quasi-static should be related to the response time of the detector. | |||

[[Image:radiationsensor.png|thumb|250px|left|Heat flux sensor as radiation detector.]] | |||

The case that the heat flux sensor is used as a radiation detector (see figure to the left) will serve to illustrate the effect of changing fluxes. Assuming that the cold joints of the sensor are at a constant temperature, and an energy flows from <math>t>0</math>, the sensor response is: | |||

<math>V_{\mathrm{sen}} = E_{\mathrm{sen}} \left( 1 - e^{- \frac{t}{\tau_{\mathrm{sen}}}} \right)</math> | |||

This shows that one should expect a false reading during a period that equals several response times, <math>\tau_{\mathrm{sen}}</math>. Generally heat flux sensors are quite slow, and will need several minutes to reach 95% response. This is the reason why one prefers to work with values that are integrated over a long period; during this period the sensor signal will go up and down. The assumption is that errors due to long response times will cancel. The upgoing signal will give an error, the downgoing signal will produce an equally large error with a different sign. It is obvious that this will only be valid if periods with stable heat flow prevail. | |||

In order to avoid errors caused by long response times, one should use sensors with low value of <math>R_{\mathrm{sen}}C_{\mathrm{sen}}</math>, since this product determines the response time. In other words: sensors with low mass or small thickness. | |||

The sensor response time equation above holds as long as the cold joints are at a constant temperature. An unexpected result shows when the temperature of the sensor changes. | |||

Assuming that the sensor temperature starts changing at the cold joints, at a rate of <math>\frac{\mathrm{d}T}{\mathrm{d}t}</math>, starting at <math>t=0</math>, <math>\tau_{\mathrm{sen}}</math> is the sensor response time, the reaction to this is:<!--whatever it is, it appears to be MISSING here--> | |||

== See also == | |||

*[[Gardon gauge]] | |||

== References == | |||

{{reflist|2}} | |||

[[Category:Sensors]] | |||

Revision as of 09:04, 30 November 2013

A heat flux sensor is a transducer that generates an electrical signal proportional to the total heat rate applied to the surface of the sensor. The measured heat rate is divided by the surface area of the sensor to determine the heat flux.

The heat flux can have different origins; in principle convective, radiative as well as conductive heat can be measured. Heat flux sensors are known under different names, such as heat flux transducers, heat flux gauges, heat flux plates. Some instruments that actually are single-purpose heat flux sensors like pyranometers for solar radiation measurement. Other heat flux sensors include Gardon gauges[1] (also known as a circular-foil gauge), thin-film thermopiles,[2] and Schmidt-Boelter gauges.[3] In SI units, the heat rate is measured in Watts, and the heat flux is computed in Watts per meter squared.

Usage

Heat flux sensors are used for a variety of applications. Common applications are studies of building envelope thermal resistance, studies of the effect of fire and flames or laser power measurements. More exotic applications include estimation of fouling on boiler surfaces, temperature measurement of moving foil material, etc.

The total heat flux is composed of a conductive, convective and radiative part. Depending on the application, one might want to measure all three of these quantities or single one out. An example of measurement of conductive heat flux is a heat flux plate incorporated into a wall.

An example of measurement of radiative heat flux density is a pyranometer for measurement of solar radiation.

An example of a sensor sensitive to radiative as well as convective heat flux is a Gardon or Schmidt–Boelter gauge, used for studies of fire and flames. The Gardon must measure convection perpendicular to the face of the sensor to be accurate due to the circular-foil construction, while the wire-wound geometry of the Schmidt-Boelter gauge can measure both perpendicular and parallel flows. In this case the sensor is mounted on a water-cooled body. Such sensors are used in fire resistance testing to put the fire to which samples are exposed to the right intensity level.

There are various examples of sensors that internally use heat flux sensors examples are laser power meters, pyranometers, etc.

We will discuss three large fields of application in what follows.[4]

Applications in meteorology and agriculture

Soil heat flux is a most important parameter in agro-meteorological studies, since it allows one to study the amount of energy stored in the soil as a function of time.

Typically two or three sensors are buried in the ground around a meteorological station at a depth of around 4 cm below the surface. The problems that are encountered in soil are threefold:

- First is the fact that the thermal properties of the soil are constantly changing by absorption and subsequent evaporation of water.

- Second, the flow of water through the soil also represents a flow of energy, going together with a thermal shock, which often is misinterpreted by conventional sensors.

- The third aspect of soil is that by the constant process of wetting and drying and by the animals living on the soil, the quality of the contact between sensor and soil is not known.

The result of all this is the quality of the data in soil heat flux measurement is not under control; the measurement of soil heat flux is considered to be extremely difficult.

Applications in building physics

In a world ever more concerned with saving energy, studying the thermal properties of buildings has become a growing field of interest. One of the starting points in these studies is the mounting of heat flux sensors on walls in existing buildings or structures built especially for this type of research.

The measurement of heat flux in walls is comparable to that in soil in many respects. Two major differences however are the fact that the thermal properties of a wall generally do not change (provided its moisture content does not change) and that it is not always possible to insert the heat flux sensor in the wall, so that it has to be mounted on its inner or outer surface. When the heat flux sensor has to be mounted on the surface of the wall, one has to take care that the added thermal resistance is not too large. Also the spectral properties should be matching those of the wall as closely as possible. If the sensor is exposed to solar radiation, this is especially important. In this case one should consider painting the sensor in the same color as the wall. Also in walls the use of self-calibrating heat flux sensors should be considered.[5]

Applications in medical studies

The measurement of the heat exchange of human beings is of importance for medical studies, and when designing clothing, immersion suits and sleeping bags.

A difficulty during this measurement is that the human skin is not particularly suitable for the mounting of heat flux sensors. Also the sensor has to be thin: the skin essentially is a constant temperature heat sink, so added thermal resistance has to be avoided. Another problem is that test persons might be moving. The contact between the test person and the sensor can be lost. For this reason, whenever a high level of quality assurance of the measurement is required, it can be recommended to use a self-calibrating sensor.

Properties

A heat flux sensor should measure the local heat flux density in one direction. The result is expressed in watts per square meter. The calculation is done according to:

Where is the sensor output and is the calibration constant, specific for the sensor.

As shown before in the figure to the left, heat flux sensors generally have the shape of a flat plate and a sensitivity in the direction perpendicular to the sensor surface.

Usually a number of thermocouples connected in series called thermopiles are used. General advantages of thermopiles are their stability, low ohmic value (which implies little pickup of electromagnetic disturbances), good signal-noise ratio and the fact that zero input gives zero output. Disadvantageous is the low sensitivity.

For better understanding of heat flux sensor behaviour, it can be modeled as a simple electrical circuit consisting of a resistance, , and a capacitor, . In this way it can be seen that one can attribute a thermal resistance , a thermal capacity and also a response time to the sensor.

Usually, the thermal resistance and the thermal capacity of the entire heat flux sensor are equal to those of the filling material. Stretching the analogy with the electric circuit further, one arrives at the following expression for the response time:

In which is the sensor thickness, the density, the specific heat capacity and the thermal conductivity. From this formula one can conclude that material properties of the filling material and dimensions are determining the response time. As a rule of thumb, the response time is proportional to the thickness to the power of two.

Other parameters that are determining sensor properties are the electrical characteristics of the thermocouple. The temperature dependence of the thermocouple causes the temperature dependence and the non-linearity of the heat flux sensor. The non linearity at a certain temperature is in fact the derivative of the temperature dependence at that temperature.

However, a well designed sensor may have a lower temperature dependence and better linearity than expected. There are two ways of achieving this:

- As a first possibility, the thermal dependence of conductivity of the filling material and of the thermocouple material can be used to counterbalance the temperature dependence of the voltage that is generated by the thermopile.

- Another possibility to minimise the temperature dependence of a heat flux sensor, is to use a resistance network with an incorporated thermistor. The temperature dependence of the thermistor will balance the temperature dependence of the thermopile.

Another factor that determines heat flux sensor behaviour, is the construction of the sensor. In particular some designs have a strongly nonuniform sensitivity. Others even exhibit a sensitivity to lateral fluxes. The sensor schematically given in the above figure would for example also be sensitive to heat flows from left to right. This type of behaviour will not cause problems as long as fluxes are uniform and in one direction only.

To promote uniformity of sensitivity, a so-called sandwich construction as shown in the figure to the left can be used. The purpose of the plates, which have a high conductivity, is to promote the transport of heat across the whole sensitive surface.

It is difficult to quantify non-uniformity and sensitivity to lateral fluxes. Some sensors are equipped with an extra electrical lead, splitting the sensor into two parts. If during application, there is non-uniform behaviour of the sensor or the flux, this will result in different outputs of the two parts.

Summarising: The intrinsic specifications that can be attributed to heat flux sensors are thermal conductivity, total thermal resistance, heat capacity, response time, non linearity, stability, temperature dependence of sensitivity, uniformity of sensitivity and sensitivity to lateral fluxes. For the latter two specifications, a good method for quantification is not known.

Error sources

The interpretation of measurement results of heat flux sensors is often done assuming that the phenomenon that is studied, is quasi-static and taking place in a direction transversal to the sensor surface. Dynamic effects and lateral fluxes are possible error sources.

Dynamic effects

The assumption that conditions are quasi-static should be related to the response time of the detector.

The case that the heat flux sensor is used as a radiation detector (see figure to the left) will serve to illustrate the effect of changing fluxes. Assuming that the cold joints of the sensor are at a constant temperature, and an energy flows from , the sensor response is:

This shows that one should expect a false reading during a period that equals several response times, . Generally heat flux sensors are quite slow, and will need several minutes to reach 95% response. This is the reason why one prefers to work with values that are integrated over a long period; during this period the sensor signal will go up and down. The assumption is that errors due to long response times will cancel. The upgoing signal will give an error, the downgoing signal will produce an equally large error with a different sign. It is obvious that this will only be valid if periods with stable heat flow prevail.

In order to avoid errors caused by long response times, one should use sensors with low value of , since this product determines the response time. In other words: sensors with low mass or small thickness.

The sensor response time equation above holds as long as the cold joints are at a constant temperature. An unexpected result shows when the temperature of the sensor changes.

Assuming that the sensor temperature starts changing at the cold joints, at a rate of , starting at , is the sensor response time, the reaction to this is:

See also

References

43 year old Petroleum Engineer Harry from Deep River, usually spends time with hobbies and interests like renting movies, property developers in singapore new condominium and vehicle racing. Constantly enjoys going to destinations like Camino Real de Tierra Adentro.

- ↑ R.Gardon, "An instrument for the direct measurement of intense thermal radiation", Rev. Sci. Instrum., 24, 366-370, 1953.

- ↑ T.E. Diller, Advances in Heat Transfer, Vol. 23, p.297-298, Academic Press, 1993.

- ↑ C.T. Kidd and C.G. Nelson, "How the Schmidt-Boelter gage really works," Proc. 41st Int. Instrum. Symp., Research Triangle Park, NC: ISA, 1995, 347-368

- ↑ Template:Cite web

- ↑ Template:Cite web