Uncertainty coefficient: Difference between revisions

en>Mcld →See also: rand index |

en>Yobot m WP:CHECKWIKI errors fixed + general fixes using AWB (8961) |

||

| Line 1: | Line 1: | ||

'''Bolt thrust''' or '''breech pressure''' is a term used in [[internal ballistics]] and firearms (whether small arms or artillery) that describes the amount of rearward force exerted by the [[propellant]] gases on the [[Bolt (firearm)|bolt]] or [[Breechblock|breech]] of a [[firearm action]] or [[Breech-loading weapon|breech]] when a projectile is fired. The applied [[force]] has both [[Euclidean vector#Length|magnitude]] and [[Direction (geometry, geography)|direction]], making it a [[Vector (geometric)|vector]] quantity. | |||

Bolt thrust is an important factor in weapons design. The greater the bolt thrust, the stronger the locking mechanism has to be to withstand it. Assuming equal engineering solutions and materiel adding strength to a locking mechanism causes an increase in weight and size of locking mechanism components.<br> | |||

Bolt thrust is not a measure to determine the amount of [[recoil]]/[[free recoil]]. | |||

==Calculating bolt thrust== | |||

With a basic calculation the bolt thrust produced by a particular firearms cartridge can be calculated fairly accurately. | |||

===Formula=== | |||

:<math>\vec{F}_{bolt} = P_{max} \cdot A_{internal}. </math> <ref>[http://www.riflebarrels.com/articles/custom_actions/bolt_lug_strength.htm A Look at Bolt Lug Strength By Dan Lilja]</ref> | |||

where: | |||

*''F<sub>bolt</sub>'' = the amount of bolt thrust | |||

*''P<sub>max</sub>'' = the maximum (peak) chamber [[pressure]] of the firearms cartridge | |||

*''A<sub>internal</sub>'' = the inside area (of the cartridge case head) that the [[propellant]] [[deflagration]] gas pressure acts against | |||

Cartridge case heads and chambers are generally [[Circle|circular]]. The [[Area of a disk|area enclosed by a circle]] is: | |||

:<math>Area = \pi r^2 \approx 3{.}1416 \cdot r^2. </math> | |||

where: | |||

*''π'' ≈ 3.1416 | |||

*''r'' = the radius of the circle | |||

Equivalently, denoting the diameter of the circle by ''d''. | |||

:<math>Area = \frac{\pi d^2}{4} \approx 0{.}7854 \cdot d^2. </math> | |||

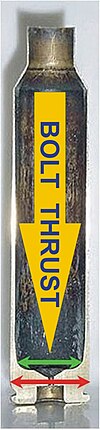

[[File:Bolt thrust.JPG|thumb|100px|The green line denotes the internal case head diameter and the red line the external case head base diameter of a rifle cartridge case.]] | |||

A practical problem regarding this method is that the internal case head diameter of a particular production lot of cartridge cases (different brands and lots normally differ dimensionally) can not be easily measured without damaging them. | |||

===Friction effects=== | |||

A complicating matter regarding bolt thrust is that a cartridge case expands and deforms under high pressure and starts to "stick" to the chamber. This "friction-effect" can be accounted for with finite elements calculations on a computer, but it is a lot of specialized work and generally not worth the trouble.<ref>[http://www.varmintal.net/abolt.htm Stolle Panda Bolt Stress and Deflection Analysis]</ref> | |||

By oiling proof rounds during [[NATO EPVAT testing]] procedures, NATO test centers intentionally lower case friction to promote high bolt thrust levels. | |||

==Practical method to estimate bolt thrust== | |||

Instead of using the internal case head diameter, the external case head base diameter can also be measured with a [[caliper]] or [[micrometer]] or taken from the appropriate [[C.I.P.]] or [[SAAMI]] cartridge or chamber data tables and used for bolt thrust estimation calculations. | |||

The basic calculation method is almost the same, but now the larger outside area of the cartridge case head is used instead of the smaller inside area. | |||

:<math>\vec{F_{bolt}} = P_{max} \cdot A_{external}. </math> | |||

where: | |||

*''F<sub>bolt</sub>'' = the amount of bolt thrust | |||

*''P<sub>max</sub>'' = the maximum (peak) chamber pressure of the firearms cartridge | |||

*''A<sub>external</sub>'' = the outside area of the cartridge case head | |||

This method is fine for getting a good estimate regarding bolt thrust and assumes an overly large area that the gas pressure acts against yielding pessimistic estimations, generating a safety margin in the process for worse case scenarios which can result in increased maximum (peak) chamber pressure of the firearms cartridge, like a round that is chambered in an already very warm [[Chamber (firearms)|chamber]] that can result in [[cooking off]] (i.e. a thermally induced unintended firing). | |||

===Bolt thrust estimations for various pistol/revolver cartridges=== | |||

{| class="wikitable" | |||

|- | |||

! | '''Chambering''' || '''P1 diameter''' (mm) || '''A<sub>external</sub>''' (cm<sup>2</sup>) || '''P<sub>max</sub>''' ([[Bar (unit)|bar]]) || '''F<sub>bolt</sub>''' ([[Kilogram-force|kgf]]) || '''F<sub>bolt</sub>''''' | |||

|-s | |||

| [[.22 Long Rifle]] || 5.74 || 0.2587 || 1,650 || 435 || {{convert|4268|N|lb-f|abbr=on}}'' | |||

|- | |||

| [[9x19 mm Parabellum]] || 9.93 || 0.7744 || 2,350 || 1,820 || {{convert|17847|N|lb-f|lk=on|abbr=on}}'' | |||

|- | |||

| [[.357 SIG]] || 10.77 || 0.9110 || 3,050 || 2,779 || {{convert|27248|N|lb-f|abbr=on}}'' | |||

|- | |||

| [[.380 ACP]] || 9.70 || 0.7390 || 1,500 || 1,130 || {{convert|11085|N|lb-f|abbr=on}}'' | |||

|- | |||

| [[.40 S&W]] || 10.77 || 0.9110 || 2,250 || 2,050 || {{convert|20101|N|lb-f|abbr=on}}'' | |||

|- | |||

| [[10 mm Auto]] || 10.81 || 0.9178 || 2,300 || 2,111 || {{convert|20701|N|lb-f|abbr=on}}'' | |||

|- | |||

| [[.45 ACP]] || 12.09 || 1.1671 || 1,300 || 1,517 || {{convert|14879|N|lb-f|abbr=on}}'' | |||

|- | |||

| [[.454 Casull]] || 12.13 || 1.1556 || 3,900 || 4,507 || {{convert|44197|N|lb-f|abbr=on}}'' | |||

|- | |||

| [[.500 S&W Magnum]] || 13.46 || 1.4229 || 4,270 || 6,076 || {{convert|59584|N|lb-f|abbr=on}}'' | |||

|} | |||

The P1 (cartridge case base) diameters and P<sub>max</sub> used in the calculations were taken from the appropriate [[C.I.P.]] data sheets. | |||

===Bolt thrust estimations for various rifle cartridges=== | |||

{| class="wikitable" | |||

|- | |||

! | '''Chambering''' || '''P1 diameter''' (mm) || '''A<sub>external</sub>''' (cm<sup>2</sup>) || '''P<sub>max</sub>''' ([[Bar (unit)|bar]]) || '''F<sub>bolt</sub>''' ([[Kilogram-force|kgf]]) || '''F<sub>bolt</sub>''''' | |||

|-s | |||

| [[5.45x39mm]] || 10.00 || 0.7854 || 3,800 || 2,985 || {{convert|29268|N|lb-f|lk=on|abbr=on}}'' | |||

|- | |||

| [[.223 Remington]] || 9.58 || 0.7208 || 4,300 || 3,099 || {{convert|30396|N|lb-f|abbr=on}}'' | |||

|- | |||

| [[7.62x39mm]] || 11.35 || 1.0118 || 3,550 || 3,592 || {{convert|35223|N|lb-f|abbr=on}}'' | |||

|- | |||

| [[.308 Winchester]] || 11.96 || 1.1234 || 4,150 || 4,662 || {{convert|45722|N|lb-f|abbr=on}}'' | |||

|- | |||

| [[.300 Winchester Magnum]] || 13.03 || 1.3335 || 4,300 || 5,734 || {{convert|56230|N|lb-f|abbr=on}}'' | |||

|- | |||

| [[.300 WSM]] || 14.12 || 1.5659 || 4,450 || 6,968 || {{convert|68334|N|lb-f|abbr=on}}'' | |||

|- | |||

| [[.300 Remington Ultra Magnum]] || 13.97 || 1.5328 || 4,480 || 6,876 || {{convert|67341|N|lb-f|abbr=on}}'' | |||

|- | |||

| [[.338 Lapua Magnum]] || 14.91 || 1.7460 || 4,200 || 7,333 || {{convert|71914|N|lb-f|abbr=on}}'' | |||

|- | |||

| [[.300 Lapua Magnum]] || 14.91 || 1.7460 || 4,700 || 8,339 || {{convert|81776|N|lb-f|abbr=on}}'' | |||

|- | |||

| [[.50 BMG]] || 20.42 || 3.2749 || 3,700 || 12,117 || {{convert|118829|N|lb-f|abbr=on}}'' | |||

|- | |||

| [[14.5x114mm]] || 26.95 || 5.7044 || 3,600 || 20,536 || {{convert|201387|N|lb-f|abbr=on}}'' | |||

|} | |||

The P1 (cartridge case base) diameters and P<sub>max</sub> used in the calculations were taken from the appropriate [[C.I.P.]] data sheets. | |||

==References== | |||

{{Reflist}} | |||

==External links== | |||

*[http://lutz-moeller-jagd.de/Waffen/Blaser/R93/Blaser-R93.html Blaser R93 Unfälle - zur Verschlußbelastung {{de icon}}] | |||

*[http://lutz-moeller-jagd.de/Waffen/Technik/Zylinderverschluss/Zylinderverschluesse.htm Zylinderverschluß - Verschlußkräfte {{de icon}}] | |||

[[Category:Firearms]] | |||

[[Category:Firearm actions]] | |||

[[Category:Firearm terminology]] | |||

[[Category:Ammunition]] | |||

Revision as of 21:09, 7 March 2013

Bolt thrust or breech pressure is a term used in internal ballistics and firearms (whether small arms or artillery) that describes the amount of rearward force exerted by the propellant gases on the bolt or breech of a firearm action or breech when a projectile is fired. The applied force has both magnitude and direction, making it a vector quantity.

Bolt thrust is an important factor in weapons design. The greater the bolt thrust, the stronger the locking mechanism has to be to withstand it. Assuming equal engineering solutions and materiel adding strength to a locking mechanism causes an increase in weight and size of locking mechanism components.

Bolt thrust is not a measure to determine the amount of recoil/free recoil.

Calculating bolt thrust

With a basic calculation the bolt thrust produced by a particular firearms cartridge can be calculated fairly accurately.

Formula

where:

- Fbolt = the amount of bolt thrust

- Pmax = the maximum (peak) chamber pressure of the firearms cartridge

- Ainternal = the inside area (of the cartridge case head) that the propellant deflagration gas pressure acts against

Cartridge case heads and chambers are generally circular. The area enclosed by a circle is:

where:

- π ≈ 3.1416

- r = the radius of the circle

Equivalently, denoting the diameter of the circle by d.

A practical problem regarding this method is that the internal case head diameter of a particular production lot of cartridge cases (different brands and lots normally differ dimensionally) can not be easily measured without damaging them.

Friction effects

A complicating matter regarding bolt thrust is that a cartridge case expands and deforms under high pressure and starts to "stick" to the chamber. This "friction-effect" can be accounted for with finite elements calculations on a computer, but it is a lot of specialized work and generally not worth the trouble.[2]

By oiling proof rounds during NATO EPVAT testing procedures, NATO test centers intentionally lower case friction to promote high bolt thrust levels.

Practical method to estimate bolt thrust

Instead of using the internal case head diameter, the external case head base diameter can also be measured with a caliper or micrometer or taken from the appropriate C.I.P. or SAAMI cartridge or chamber data tables and used for bolt thrust estimation calculations.

The basic calculation method is almost the same, but now the larger outside area of the cartridge case head is used instead of the smaller inside area.

where:

- Fbolt = the amount of bolt thrust

- Pmax = the maximum (peak) chamber pressure of the firearms cartridge

- Aexternal = the outside area of the cartridge case head

This method is fine for getting a good estimate regarding bolt thrust and assumes an overly large area that the gas pressure acts against yielding pessimistic estimations, generating a safety margin in the process for worse case scenarios which can result in increased maximum (peak) chamber pressure of the firearms cartridge, like a round that is chambered in an already very warm chamber that can result in cooking off (i.e. a thermally induced unintended firing).

Bolt thrust estimations for various pistol/revolver cartridges

| Chambering | P1 diameter (mm) | Aexternal (cm2) | Pmax (bar) | Fbolt (kgf) | Fbolt |

|---|---|---|---|---|---|

| .22 Long Rifle | 5.74 | 0.2587 | 1,650 | 435 | Template:Convert |

| 9x19 mm Parabellum | 9.93 | 0.7744 | 2,350 | 1,820 | Template:Convert |

| .357 SIG | 10.77 | 0.9110 | 3,050 | 2,779 | Template:Convert |

| .380 ACP | 9.70 | 0.7390 | 1,500 | 1,130 | Template:Convert |

| .40 S&W | 10.77 | 0.9110 | 2,250 | 2,050 | Template:Convert |

| 10 mm Auto | 10.81 | 0.9178 | 2,300 | 2,111 | Template:Convert |

| .45 ACP | 12.09 | 1.1671 | 1,300 | 1,517 | Template:Convert |

| .454 Casull | 12.13 | 1.1556 | 3,900 | 4,507 | Template:Convert |

| .500 S&W Magnum | 13.46 | 1.4229 | 4,270 | 6,076 | Template:Convert |

The P1 (cartridge case base) diameters and Pmax used in the calculations were taken from the appropriate C.I.P. data sheets.

Bolt thrust estimations for various rifle cartridges

| Chambering | P1 diameter (mm) | Aexternal (cm2) | Pmax (bar) | Fbolt (kgf) | Fbolt |

|---|---|---|---|---|---|

| 5.45x39mm | 10.00 | 0.7854 | 3,800 | 2,985 | Template:Convert |

| .223 Remington | 9.58 | 0.7208 | 4,300 | 3,099 | Template:Convert |

| 7.62x39mm | 11.35 | 1.0118 | 3,550 | 3,592 | Template:Convert |

| .308 Winchester | 11.96 | 1.1234 | 4,150 | 4,662 | Template:Convert |

| .300 Winchester Magnum | 13.03 | 1.3335 | 4,300 | 5,734 | Template:Convert |

| .300 WSM | 14.12 | 1.5659 | 4,450 | 6,968 | Template:Convert |

| .300 Remington Ultra Magnum | 13.97 | 1.5328 | 4,480 | 6,876 | Template:Convert |

| .338 Lapua Magnum | 14.91 | 1.7460 | 4,200 | 7,333 | Template:Convert |

| .300 Lapua Magnum | 14.91 | 1.7460 | 4,700 | 8,339 | Template:Convert |

| .50 BMG | 20.42 | 3.2749 | 3,700 | 12,117 | Template:Convert |

| 14.5x114mm | 26.95 | 5.7044 | 3,600 | 20,536 | Template:Convert |

The P1 (cartridge case base) diameters and Pmax used in the calculations were taken from the appropriate C.I.P. data sheets.

References

43 year old Petroleum Engineer Harry from Deep River, usually spends time with hobbies and interests like renting movies, property developers in singapore new condominium and vehicle racing. Constantly enjoys going to destinations like Camino Real de Tierra Adentro.